If you are looking for a new countertop for your kitchen, bathroom, or any other area of your house, then Porcelain countertops is worth considering.

Because it can be used as a countertop, flooring, or sink material. The advantages of this countertop are plentiful and it is durable, resistant to stains, and simple to maintain.

Porcelain slabs are available in a variety of designs and colors, allowing you to find the perfect match for your kitchen. Also, it come in different dimensions, facilitating easy installation in your home.

What is porcelain made of?

It is kind of hard, white pottery, and it was first made in China in the 13th century. Porcelain is a type of pottery and ceramic material that is translucent and pigmented. In the modern era, it is primarily used for tableware and decorative items.

It is made of a mixture of the clay mineral kaolinite with small quantities of the minerals quartz and feldspar. Porcelain is a vitreous or semi-vitreous ceramic typically white or off-white in color.

Mixing a clay body with bone ash or an artificial substitute creates it. The process involves blending white clay with feldspar, a mineral group abundant in the Earth’s crust.

Heating the clay to high temperatures and adding feldspar result in the formation of a hard, solid, and durable material.

Read More: Best Trivets for Countertops and Tables

Porcelain countertops Vs Dekton countertops

- The main difference between porcelain and dekton countertops lies in their manufacturing processes, the specific methods involved, and the raw materials required for each.

- Dekton countertops evolved from porcelain and are stronger than porcelain countertops.

- Porcelain do not contain quartz as their ingredients while dekton countertops contain a combo of quartz, granites, and tiles that make them harder and long-lasting.

- Dekton countertops require regular sealing while porcelain do not require re-sealing.

- Moreover, porcelains are lighter in weight and density that making their travel easy but dekton countertops are heavier in density and more thickness.

- The fabrication process for Dekton countertops goes by the name Sinterized, and it involves subjecting porcelains to extremely high temperatures.

- While damage to these countertops is irreversible, Dekton countertops can undergo repairs if they sustain damage.

Read More: Labradorite Countertop

Edge Styles

Porcelain edge styles are more limited than natural stone or quartz since the patterns are just skin-deep. The pattern would be removed by cutting a fancy edge with rounded corners, bevels, and grooves.

When compared to other countertop materials, porcelain countertop edges are a little different. While it is possible to generate all the standard edges like round, beveled, straight, bullnose, ogee, cove, platner, waterfall, and others… you may not like the look of any of these.

On the other hand, craftsmen can miter porcelain countertop edges in a variety of ways to maintain a consistent pattern over the edge. The majority of people prefer a square edge.

Read More: Azul Platino Granite

Size and Thickness

This countertops are available in different dimensions ranging from 1*2, 1.50*2.50,3*4 (feet) to more 6*7, 8*10, 12*14,16*18 (feets).

However, the thickness and density of these material countertops are slightly less or lower, making them more delicate and easily broken into small pieces. Due to its low thickness, it is less durable than other quartz countertops.

Installation Options

It very easy to install in our kitchens, interior walls, floors, bathrooms, etc by humans because of their lighter weight. The bigger slab size of porcelains has fewer cuts and seams. Porcelain is an easy-to-install product because of this, as well as its less weight. However, it is not suitable for do-it-yourself installation.

Advantages

Durability

Porcelain is a durable material that is not only beautiful but also durable. It is resistant to bacteria, and stains, and will not scratch. It is also easy to clean with a simple soap and water solution.

The raw materials used for manufacturing porcelain are high grade and top quality which makes them strong enough for long life.

They can also be used for cooking purposes as well. They are stronger than normal tiles, marbles, granites, etc.

Read More: Hydraulic Cement

Finishes

Choosing the right finish for your countertops is one of the most important decisions you’ll make. It will have a significant impact on the look of your kitchen, including the colors and textures of your cabinets and cabinetry, and the feel of your new countertops.

Also, this countertops are available in a variety of finishes including matte/honed finish, and high glossy polished finish.

The most popular finish is a glossy, high-luster finish that is easy to clean and resists scratches and stains. Quality finishing of any materials will provide ultimate results to us.

The matte/honed finish is the most durable of the three finishes, as it is not as susceptible to scratches or stains.

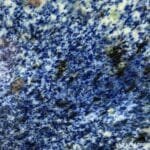

Pattern and colors

Because these countertops are largely handmade, they come in a variety of colours, patterns, hues, and designs.

The colors range from red, yellow, green, white, black, and orange, mixed colors include white-black, silver-gold, red-green, and many colors, the list is endless. Different colors of porcelain always add beauty to our homes, especially in kitchens.

We can manufacture porcelain with any color combination and design for the perfect look and decoration of kitchens.

There are many patterns of porcelain including ring-like structure, willow shape, diamond shape, star appearance, circled look, building looks, car-structured, and many more. The tree trunk patterns are more prevalent as most people like woody structures.

Read More: Parquet Flooring

Cost

The cost of porcelain countertops depends on their quality, the types of raw materials ṣused for making them, and the manufacturer countries. In a separate section, we break down the pricing of this countertops.

In brief, slab will cost $40 to $120 per square foot to install, depending on the material, the style of edge you have loved into it (if any), and the job’s intricacy.

The higher the cost per square foot, the more corners, cutouts, and seams there are. They are costlier than other types of quartz countertops and tiles or marbles.

Installation options and designs

The installation process of this countertops is very easy and comfortable. Their lightweight and small sizes make them easy to install anywhere.

Carrying and transporting this countertops takes little time as compared to marbles and heavy-sized granites. They can also be applied over existing tiles and marbles or any other countertops.

People also utilize them in flooring, bathroom walls, laundry areas, and to some extent, interior walls. Many attractive designs are also available, such as potteric, toys, forestry, rivers, etc.

Read More: Black Galaxy Granite

Heat and acid-resistant

We all know that manufacturers create these types of countertops by heating them to incredibly high temperatures and adding a range of chemicals.

They are high heat, temperature, and acid resistant and do not let the bacteria rise and sustain. They are also less prone to chemicals and cleaning agents.

Their colors and designs also do not fade with increasing temperature, thus they always look new. They are also recyclable i-e the used porcelain can again be used on some other parts.

People also utilize them in kitchen cabinets, wall panels, and decorative assets in our homes..

Dimensions And availability

This countertops are mostly available in small slabs or sizes with dimensions of 1*2, 1.50*2.50,3*4 (feet), and many according to our home requirements and the type of building we are making.

Availability largely depends on demand and areas like urban, metropolitan, and rural. They are mostly preferred in villages and towns and some villagers even make them on their own.

Protection from Stain and UV rays

This is one of the unique features of this countertops protecting it from harmful ultraviolet rays coming from the sun. They have a protective layer for UV rays.

These are also stain-free and stains do not stick to them for a longer time this increases their pleasant appearance.

Read More: River White Granite

Disadvantages

Smooth/Fragile

Countertops made of this material are extremely soft, lightweight, and easily cut or damaged. Even a small tool or iron has the potential to break or damage it.

During shipment, a large number of countertops get damaged.

While cutting them, many cut pieces are wasted. We should also be careful while cleaning them with any fluids and chemicals.

Read More: How to Cut Granite

Less availability

This countertops are less in demand, customers find them difficult to buy and locate. Due to high demands and more stock of granites, tiles, and marbles porcelain itself finds it difficult to compete with them.

Also, there are very few manufacturers and factories of this material countertops. Price is also the main concern for less availability of porcelain.

Artificial shades

The designs and shades over this countertops are not natural, manufacturers make and apply attractive designs and shades over the finished porcelain products. That’s Why we are not familiar with the natural look of porcelain.

How To Clean Porcelain Countertops

It is simple to clean the surface of a porcelain countertop. Here are some key cleaning steps for porcelain countertops.

- Considering the fact that this material countertops are acidic and chemically resistant, we should avoid using chemical-containing solutions to clean their surfaces.

- Simply wash spills with warm water and wipe it away with a clean cloth.

- After washing it with the soap mixture, wash it with water and dry it with a clean cloth.

- Sanitise the surface with neutral liquid soaps or detergents. This approach significantly improves the sanitary appearance.

- To avoid scratch marks and a loss of gloss, make sure to use non-abrasive wipes or cloth.

Maintenance, Cleaning, and Repairs

This material countertop requires regular maintenance to maintain its dynamic and interesting appearance. If you use toxic chemicals like ammonia, you won’t have any trouble.

On the other hand, natural stone has pores that can collect water, bacteria, oil, and other elements that make it unclean and cause stains and discoloration, especially when the sealer breaks down with time.

The finish produces a water-resistant, easy-to-clean surface. Typically, cleaning a sanitary surface involves using warm water or rubbing it with a moist cloth.

If any part sustains damage, we must remove the entire single piece and install another porcelain countertop.

Read More: Knockdown Texture

Slabs