Hydraulic cement is also known as portland cement, is the most common type of cement in general use around the world because it sets and hardens quickly. This is a fine powder that can be set underwater.

Because cement is a binder substance that sets and hardens independently and is used to bind other materials together. It is the most widely used man-made material in the world. You can not know it by this name though as it goes by many different names, such as concrete, mortar, stucco, and plaster.

There are many types of hydraulic cement but all of them contain several major components such as limestone, shale, and clay.

These materials are mixed with water to form a paste or concrete mixture and then it is sometimes combined with aggregates like sand or gravel

It refers to a type of concrete which is created when water and Portland cement are mixed together. While cement has been around for many centuries, hydraulic cement’s history is a little more complicated.

For example, it was first invented in 1824 by Dr. John Smeaton, who discovered that mixing water with portland cement (otherwise known as white cement) created a much stronger substance than the original.

Difference Between Hydraulic and Non-Hydraulic Cement

- Lot of people are confused about the difference of hydraulic and non-hydraulic cement. When dealing with these two types of concrete it is important to note that they have different qualities.

- Non-hydraulic concrete is created without use of water or mixing water with other ingredients during the production process. On the other hand, is created by mixing water with other ingredients during the production process.

- It cannot be stored for long periods of time, and need to be mixed with water before every use. Non-hydraulic can be stored longer than 24 hours without losing its effectiveness.

- It requires heat curing while non-hydraulic does not require heat curing.

- It is a concrete that is used in the construction industry. Because it has a consistency between that of a liquid and a solid as it contains both water and aggregates. It is usually gray-colored because it contains aluminum oxide, which can also be found in paint and phosphoric acid.

- Non-hydraulic contains Sodium carbonate and Silicon dioxide as the main ingredients. The materials required for making non-hydraulic cement are the same as those for making hydraulic cement. The difference is the method used to mix the ingredients together.

See also: Sanded vs Unsanded Grout

How to Make Hydraulic Cement

It is a kind of natural cement that is made by burning a mixture of limestone and clay. It is used for the production of concrete and mortar and also for the restoration of historic structures. We will take a look at how to make cement.

Firstly, fire clay or shale mixed with limestone must be heated in order to create a stable lime product. The mixture is then slaked with cold water to create hydraulic lime that can be stored in a dry place.

To make cement, you mix two parts of this lime with one part of sand and one part of gravel. The mixture is then ground until it has the consistency of coarse flour before water is added to activate it.

How to Mix Hydraulic Cement

The hydraulic process of mixing cement involves adding water to the cement at a ratio of 1:4 by weight for quick-setting cement and 1:5 for traditional cement.

Also hydrostatic pressure is a force that pushes a liquid or gas through a closed system. Mixing cement and water together creates this type of pressure. When you mix the two, it changes the density of the cement granules in order to form a slurry.

It increased density forces water out of the mixture, which creates dust-laden bubbles that eventually pop and release water vapor. It is important to mix the cement and water in order to create hydration.

First, you will need to find a container (big enough for the size of the job) that is made of metal or plastic.

Next, pour water into it and mix in the quick setting compound until it is thoroughly dissolved.

Then, slowly add the dry cement powder, stirring until fully mixed. You have now successfully mixed cement and can start building whatever you please!

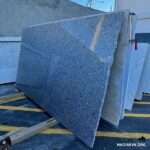

See also: Types of White Marble

How to Apply Hydraulic Cement

Laying cement or concrete is a challenging task for any homeowner and not everyone has the tools to do it. But anyone can purchase a bag of cement, mix it with water and apply it to the surface in need.

It is a kind of concrete which is made of cement, sand, and water. Also it has characteristics of fluidity, simplicity, and convenience.

It’s commonly used in the following way: mix the components together and add water to make a paste; spread it on the ground after leaving it for a while, you can use a trowel to shape it into what you want or need.

Also it can be used as building materials, non-standard blocks, aggregate for asphalt pavement, and so on.

See Also: Valle Nevado Granite

Advantages

This is lightweight and set faster. It has relatively low coke and carbon dioxide emissions. Because it is ideal for high-temperature applications, and therefore often used in the manufacture of high-temperature equipment.

Disadvantages

The main disadvantage is that it can be a bit more expensive than other types of cement. This is because hydraulic is much more energy intensive to manufacture than traditional cement.